Blowers play a crucial role in wastewater treatment, primarily in aeration processes that provide oxygen to microorganisms responsible for breaking down organic matter. Positive displacement (PD) blowers, such as two- and three-lobe rotary blowers, are widely used in many wastewater treatment plants (WWTPs). However, certain wastewater applications call for more advanced technologies, such as turbo blowers. These blowers offer significant advantages in efficiency, energy consumption, and maintenance requirements.

What Makes Turbo Blowers Different

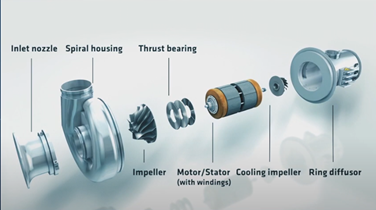

Unlike PD blowers, which trap and push air through mechanical displacement, turbo blowers use high-speed impellers powered by direct-drive motors to accelerate air and create pressure through dynamic compression. This produces a more continuous and uniform airflow compared to PD blowers. As a result, turbo blowers operate at much higher efficiency levels, often achieving energy savings of 20% to 40% over PD blowers. Turbo blowers also incorporate variable frequency drives (VFDs) to change speed and airflow dynamically without needing mechanical adjustments.

Altogether, turbo blowers boast a number of noteworthy advantages over traditional PD blowers:

Lower operating costs. With up to 80% of WWTP energy costs coming from aeration, the reduced energy consumption of turbo blowers translates to significant long-term savings. In addition, turbo blowers have fewer moving parts, which cuts down on maintenance costs and wear-related failures.

Minimal pulsation and noise. Turbo blowers provide a steady, non-pulsating airflow, which enhances aeration system stability. They also operate at significantly lower noise levels compared to PD blowers, reducing the need for additional noise control measures.

Compact design and flexible operation. The compact footprint of turbo blowers makes them ideal for retrofits and plants with space limitations. Their ability to modulate speed efficiently allows for precise aeration control in response to real-time oxygen demand.

Applications For Turbo Blowers

Turbo blowers excel in various wastewater treatment applications but are not universally suitable for all scenarios. Their ability to precisely control speeds and airflow makes them ideal for high-pressure applications that require continuous flow, including activated sludge basins, membrane bioreactors, industrial water treatment, and more.

However, for low-pressure applications, PD blowers may be more cost-effective. That’s because the lower energy requirements often mean the energy savings fail to justify the higher upfront cost. In addition, if the air demand varies drastically over short periods, certain turbo blower models may struggle with quick response times compared to PD blowers. Similarly, turbo blowers operate best when running continuously or with gradual speed adjustments. Repeated cycling on and off can reduce efficiency and increase wear on the bearings. Additionally, unlike PD blowers, turbo blowers are generally designed for indoor installations only.

Maintenance Considerations For Turbo Blowers

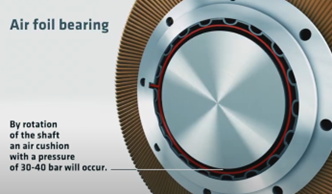

One of the most attractive features of turbo blowers is their low maintenance requirements, compared to PD and other blower types. With no timing gears or oil-lubricated bearings, turbo blowers have fewer mechanical components, reducing the likelihood of failure. Instead, turbo blowers use air foil or magnetic bearings, which eliminate the need for oil changes, minimize vibrations, and allow for elevated rotation with no friction

Of course, turbo blowers still require periodic upkeep to ensure optimal performance. They rely on clean, dry air for efficient operation. As such, air intake filters must be inspected and replaced periodically by plant personnel to prevent contamination. Unlike PD blowers, which require routine belt and rotor inspections, turbo blowers primarily require performance monitoring to detect any operational anomalies. In addition to replacing the package air filters, a yearly preventative maintenance inspection by a certified factory technician is recommended. The maintenance includes motor, inverter (VFD), and blow off valve inspections, emergency stop functionality verification, inspection of electrical components, and complete instrumentation calibration. The system parameters are then tuned to achieve optimal performance and prevent unsafe conditions. In addition, CPU and HMI software may be updated.

Air Foil Bearings Vs. Magnetic Bearings

Air foil bearings (Figure 2) suspend the shaft on a cushion of air provided by the system while it is running. During hard stops, the air will be sufficient to allow the shaft to maintain the cushion while the system ramps down. They feature a double coating made of Teflon and graphite, with a theoretical life of over 80,000 operating hours regardless of stop and start cycles. They also feature a bump foil to dampen vibrations or unexpected movement of the rotor, making them resistant to surges. Air foil bearings are maintenance free and do not require additional accessories. They are economical and can be replaced in the field.

Turbo blowers with magnetic bearings (Figure 3) have radial and thrust bearings on both the impeller and fan side of the shaft. Additionally, there are two touch-down bearings in case of power failure. The magnetic bearing system consists of eight coils, eight position sensors, a digital bearing control system, and a backup battery system for power failures. Magnetic bearings require service on the backup batteries. If the bearings fail, they will need to be replaced at a service center.

Surge

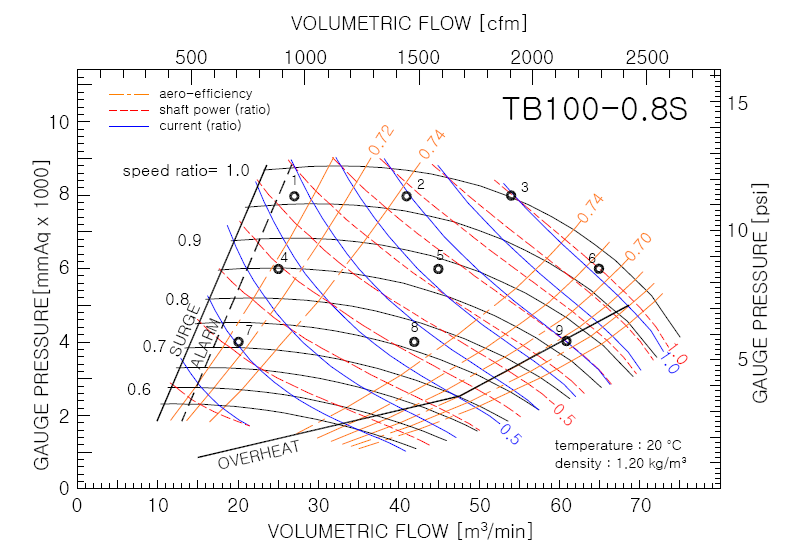

Surge occurs when the turbo blower is unable to continue working against the already compressed air behind it, leading to a rapid and cyclical reversal of airflow. The surge line is the lower operational limit for a turbo, and operating below this line will lead to mechanical failure. See the surge line below.

Surge can occur when there are sudden and significant pressure fluctuations in the system. There are several common causes of surge in a turbo blower. These include, for example, operating below the minimum stable flow rate for a given pressure (the surge line in the figure above), sudden load changes caused by unstable power to the motor, improper maintenance, such as dirty filters, impeller blades, diffusers, and air coolers, or excessive exhaust backpressure.

Surge Prevention

Surge produces rapid thrust reversals that can cause excess vibrations and mechanical stress on the impeller, shaft, and bearings. In addition, the recycling of hot gases causes a rapid temperature increase. These factors often lead to mechanical failure. Turbo blower controls use instrumentation to detect early signs of aerodynamic instability (see alarm line in the figure above) to prevent surge from occurring. Additional anti-surge systems, such as blow-off valves are also used to release excess pressure and reroute air back to the inlet, ensuring continuous forward flow. However, the system must be tuned periodically to operate safely between the surge and overheat lines. Tuning will also ensure the motor current is within safe limits to prevent electrical overload. In addition, tuning ensures maximum efficiency, reliability, and performance.

Turbo blowers represent a significant advancement in wastewater aeration technology, offering greater energy efficiency, reduced maintenance, and quieter operation compared to traditional PD blowers like three-lobe rotary blowers. Their ability to dynamically adjust output makes them ideal for a range of wastewater applications. With proper maintenance, turbo blowers can be a reliable, cost-saving solution.