Portland's industry-leading facility reaches 100 reactor validations in 23 years.

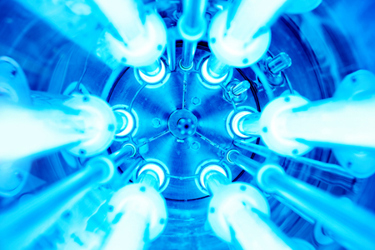

The Portland UV Disinfection Validation Facility reached a significant milestone at the end of June 2025, marking 23 years of operation with the completion of its 100th UV reactor validation.

This achievement reflects more than just operational longevity — it represents the facility’s essential role in establishing UV disinfection standards that protect public health worldwide.

As the only test facility of its kind in North America and the largest of four worldwide, the Portland facility’s influence extends far beyond the Pacific Northwest. Its work has directly shaped how cities around the world approach UV disinfection.

Origins And Development

In December 2002, Carollo Engineers partnered with the Portland Water Bureau (PWB) to establish this UV Validation Facility. Carollo's collaboration was in response to the U.S. EPA’s 2003 draft UV Disinfection Guidance Manual (USEPA UVDGM), which required full-scale validation testing of commercial UV systems used for drinking water applications.

The facility has grown significantly since its early days, when it relied on diesel generators for power and rented party tents for shelter. Today, it boasts multiple test trains, including supply lines of 12, 24, and 30 inches in diameter and multiple discharge lines up to 48 inches in diameter for high-flow testing. It also features a 500 KVA electrical service to accommodate the most powerful UV reactors, as well as an enclosed building for system operations.

Global Significance And Impact

The facility has significantly contributed to UV industry research, which has driven optimization of UV disinfection practices, design, and performance guidelines for UV sensor systems, as well as provided guidance for implementing action spectra correction factors with medium-pressure UV disinfection. It has also played a role in developing computational fluid dynamics (CFD)-based models for assessing UV reactor design and installation.

To date, the facility has completed 100 validations of commercial UV reactors from 17 international UV system manufacturers for drinking water, wastewater, water reuse, and advanced oxidation processes at flows ranging from 5 gpm to 72 MGD.

A 2022 survey of the three largest UV equipment suppliers indicated that nearly 300 cities around the globe use UV reactors validated in Portland, with a total design treatment capacity exceeding 13 billion gallons per day.

Contribution To Regulatory Standards And Innovation

The Portland UV Validation Facility’s work has directly influenced the regulatory landscape, contributing to innovative approaches for validating UV disinfection reactors for drinking water systems. These innovations include standardizing UV dose algorithms, improving quality assurance and quality control, and establishing UV dose values for 6-log pathogen inactivation for potable reuse.

Moreover, new UV dose algorithms developed at the facility eliminate the need for on-line UV transmittance monitors, making UV disinfection more accessible for small systems.

The facility has been instrumental in shaping key documents, such as the final USEPA UVDGM released in 2006, EPA’s Innovative Approaches for Validation of Ultraviolet Disinfection Reactors for Drinking Water Systems released in 2020, and the National Water Research Institute (NWRI) Guidelines for Implementing UV Technologies for Disinfection, Photolysis, and Advanced Oxidation released in 2025.

These documents have defined the application of UV disinfection worldwide.

Collaborations And Future Directions

In 2016, Carollo established a collaborative agreement with the German TZW: DVGW-Technologiezentrum Wasser (German Water Centre), allowing UV manufacturers to test reactors using both USEPA UVDGM and Deutsches Institut fur Normung (DIN) European standards at a single location in either Portland or Germany. This collaboration has reduced the time and costs associated with multiple validations.

Furthermore, the higher flow capacity of the Portland facility allows for testing larger reactors intended for installation in Europe. To date, manufacturers have conducted 12 UV validations under USEPA UVDGM standards in Germany, and six validations under the European DIN standards in Portland.

With the demand for UV validation increasing, especially for direct potable reuse applications requiring UV advanced oxidation processes and for emerging UV light-emitting diode (LED) technologies, Carollo is dedicated to maintaining the Portland UV Validation Facility as a state-of the-art resource, reflecting its unique and global significance.